At a Glance

- Plastic Bottles: HDPE is the preferred material for blow-moulding applications, particularly for food and beverage containers.

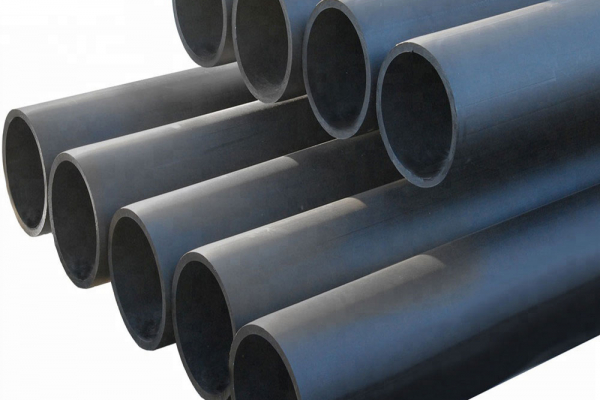

- Pipe Systems: HDPE’s durability and UV resistance make it suitable for piping in industrial and outdoor applications.

- Outdoor Furniture and Equipment: HDPE’s weather resistance makes it ideal for outdoor products like patio furniture and playground equipment.

High-Density Polyethylene (HDPE) is a versatile and widely used thermoplastic polymer with applications spanning numerous industries. Its exceptional properties, including high tensile strength, impact resistance, and chemical resistance, make it an ideal choice for a variety of products. In this article, we will explore the five most common applications of HDPE, highlighting its advantages and importance in each area.

The most common applications of HDPE

1. Plastic Bottles

One of the most prevalent applications of HDPE is in the production of plastic bottles. Due to its impressive tensile strength and chemical resistance, HDPE is an excellent choice for blow-moulding applications. It is commonly used to manufacture food and beverage containers because it does not leach into the contents, ensuring the safety and quality of the products. Additionally, HDPE bottles are recyclable, making them a sustainable choice for highly disposable products.

In the food production, wine bottling, and beverage processing industries, HDPE’s non-leaching property is crucial. It ensures that the contents remain uncontaminated, maintaining the taste and quality of the products. This makes HDPE an essential material for these industries in Shepparton and Goulburn.

2. Pipe Systems

HDPE’s durability and resistance to a wide range of chemicals make it an excellent material for pipe systems. HDPE pipe-grade sheets have a higher molecular weight than standard HDPE, enhancing their strength and UV resistance. This makes HDPE pipes suitable for both industrial and outdoor applications, capable of withstanding temperatures ranging from -220 to 180 degrees Fahrenheit.

The use of HDPE pipes is prevalent in various industries, including food machinery manufacturing and canning, where durability and resistance to harsh chemicals are essential. HDPE pipes ensure reliable performance and longevity, reducing maintenance costs and downtime.

3. Outdoor Furniture and Equipment

HDPE’s weather-resistant properties make it an ideal material for outdoor furniture and equipment. It is resistant to mould, mildew, rotting, and insects, ensuring that products remain in good condition even when exposed to the elements. HDPE can be easily moulded into various shapes, making it perfect for products like outdoor patio furniture, playground equipment, and storage containers.

In regions like Murray Valley and Southern NSW, where outdoor activities are popular, HDPEs are particularly beneficial. HDPE products maintain their appearance and functionality, providing long-lasting value for consumers.

4. Industrial and Chemical Containers

HDPE is widely used for manufacturing industrial and chemical containers due to its excellent chemical resistance. It is commonly used to produce bottles for laundry detergents, shampoos, conditioners, household cleaning products, motor oils, and antifreeze. Coloured or pigmented HDPE bottles have increased strength, ensuring that they can withstand the harsh conditions of chemical storage.

HDPE’s chemical resistance also benefits niche products for the food and beverage processing industries. Containers made from HDPE ensure that the contents remain safe and uncontaminated, meeting the stringent standards of the food industry.

5. Cutting Boards and Kitchen Products

In addition to industrial applications, HDPE is popular for various kitchen products. Its durability, low maintenance, and FDA compliance make it an excellent material for cutting boards, shelving, counters, tables, and small appliances. HDPE cutting boards, in particular, are prized for their textured surfaces, which provide an adequate grip for secure food handling.

The food production and niche products industries in Southern NSW and surrounding regions rely on HDPE for its safe and hygienic properties.

HDPE’s versatility, strength, and chemical resistance make it an invaluable material across various industries. From plastic bottles and pipe systems to outdoor furniture and kitchen products, HDPE’s properties ensure durability, safety, and sustainability. In regions like Shepparton and Southern NSW, HDPE continues to play a crucial role in supporting industries such as food production, wine bottling, beverage processing, and canning.

By understanding the most common applications of HDPE, businesses and consumers can make informed decisions, leveraging the advantages of this exceptional material to meet their specific needs.